Computer Manufacturing: Tech Skill Empowerment

Introduction

The computer manufacturing industry stands at the forefront of technological innovation, driving advancements that shape our digital world. As the demand for more powerful, efficient, and sophisticated computing devices continues to grow, so does the need for a highly skilled workforce capable of designing, producing, and maintaining these complex systems. We will explore the critical role of training and development in empowering tech skills within the computer manufacturing sector, addressing the unique challenges and opportunities faced by this dynamic industry.

Transformations in Computer Manufacturing: Navigating Industry Evolution

Computer manufacturing has undergone significant transformations since the advent of personal computers in the late 20th century. Today, the industry encompasses a wide range of products, from traditional desktop and laptop computers to smartphones, tablets, wearables, and specialized computing devices for various industries. This diversity in product offerings, coupled with rapid technological advancements, creates a constant need for skill upgrades and knowledge acquisition among workers in the field.

Key areas of focus in modern computer manufacturing include:

- Semiconductor design and fabrication

- Printed circuit board (PCB) assembly

- System integration and testing

- Quality control and assurance

- Supply chain management

- Research and development in emerging technologies

Each of these areas requires a unique set of skills and expertise, making comprehensive training and development programs essential for maintaining a competitive edge in the industry.These skill sets often overlap and intersect, requiring professionals in computer manufacturing to have a broad understanding of the entire production process while also developing deep expertise in their specific areas. Additionally, soft skills such as communication, teamwork, adaptability, and problem-solving are crucial across all these domains.

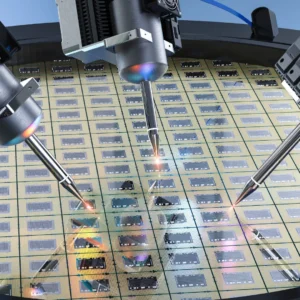

Semiconductor Design and Fabrication

- Skills Needed: Expertise in electronic engineering, solid-state physics, and nanoscale manufacturing techniques.

- Expertise Required: Proficiency in CAD tools for chip design, knowledge of photolithography and etching processes, understanding of VLSI design principles, familiarity with clean room protocols.

Printed Circuit Board (PCB) Assembly

- Skills Needed: Proficiency in PCB design software, understanding of electronic component placement and routing.

- Expertise Required: Knowledge of soldering techniques and surface mount technology (SMT), familiarity with automated assembly processes, understanding of thermal management in PCB design, expertise in testing and troubleshooting PCB assemblies.

System Integration and Testing

- Skills Needed: Strong problem-solving and analytical skills, proficiency in various operating systems and software environments.

- Expertise Required: Understanding of hardware-software interactions, knowledge of system architecture and component compatibility, expertise in diagnostic tools and testing methodologies, skills in performance optimization and benchmarking.

Quality Control and Assurance

- Skills Needed: Attention to detail, strong analytical capabilities, proficiency in statistical methods.

- Expertise Required: Understanding of statistical process control (SPC) methods, knowledge of quality management systems (e.g., ISO 9001), expertise in failure analysis techniques, familiarity with reliability testing procedures and metrology.

Supply Chain Management

- Skills Needed: Strong organizational and communication skills, ability to manage complex logistics.

- Expertise Required: Knowledge of logistics and inventory management, understanding of global trade regulations, proficiency in supply chain management software and ERP systems, expertise in demand forecasting and production planning.

Research and Development in Emerging Technologies:

- Skills Needed: Strong background in computer science and engineering, creativity and innovative thinking.

- Expertise Required: Knowledge of emerging technologies (e.g., AI, IoT, quantum computing), proficiency in relevant programming languages, skills in prototyping and proof-of-concept development, expertise in intellectual property processes

The Skills Gap in Computer Manufacturing

Despite the growing demand for tech-savvy professionals, the computer manufacturing industry faces a significant skills gap. This disparity between the skills required by employers and those possessed by the available workforce can be attributed to several factors:

- Rapid technological advancements

The pace of innovation in computing technology often outstrips the rate at which educational institutions can update their curricula.

- Increasing complexity of systems

Modern computing devices integrate various technologies, requiring workers to have a broader range of skills and knowledge.

- Globalization of supply chains

The distributed nature of computer manufacturing necessitates skills in cross-cultural communication, logistics, and international regulations.

- Shift towards automation and Industry 4.0

As manufacturing processes become more automated, workers need to adapt to new roles that involve managing and maintaining these systems.

- Emergence of new materials and manufacturing techniques

Innovations such as 3D printing and advanced materials require continuous learning and skill development.

Addressing this skills gap is crucial for the sustained growth and competitiveness of the computer manufacturing industry. Effective training and development programs play a pivotal role in bridging this gap and ensuring a workforce capable of meeting the industry’s evolving needs.

Strategies for Effective Tech Skills Training

Comprehensive Onboarding Programs

Developing robust onboarding programs is essential for integrating new employees into the complex world of computer manufacturing. These programs should provide:

- An overview of the industry and company-specific processes

- Basic training in relevant technologies and manufacturing techniques

- Introduction to quality control standards and safety protocols

- Familiarization with the company’s culture and values

Effective onboarding sets the foundation for continuous learning and helps new hires become productive members of the team more quickly.

Modular and Adaptive Learning Pathways

Given the diverse skill sets required in computer manufacturing, implementing modular and adaptive learning pathways allows employees to tailor their training to their specific roles and career aspirations. This approach may include:

- Core modules covering fundamental concepts in computer manufacturing

- Specialized tracks for different areas of expertise (e.g., semiconductor design, PCB assembly)

- Advanced modules for emerging technologies and industry trends

- Soft skills training for leadership and communication

By offering flexible learning options, companies can ensure that employees develop the most relevant skills for their current and future roles.

Hands-on Training and Simulation

Practical, hands-on experience is crucial in the manufacturing industry. Incorporating hands-on training and simulation into development programs helps employees apply theoretical knowledge to real-world scenarios. This can be achieved through:

- Dedicated training facilities that replicate actual manufacturing environments

- Virtual and augmented reality simulations for complex or hazardous processes

- Apprenticeship programs that pair novice workers with experienced mentors

- Regular practice sessions on actual manufacturing equipment

These hands-on approaches not only enhance skill development but also improve safety awareness and problem-solving abilities.

Cross-functional Training and Job Rotation

Encouraging cross-functional training and job rotation helps employees gain a broader understanding of the manufacturing process and develops versatility within the workforce. Benefits of this approach include:

- Enhanced problem-solving skills through exposure to different perspectives

- Improved communication and collaboration across departments

- Increased flexibility in workforce allocation

- Identification of talent for future leadership roles

Implementing structured job rotation programs can significantly contribute to building a more adaptable and knowledgeable workforce.

Partnerships with Educational Institutions

Collaborating with universities, technical colleges, and vocational schools can help computer manufacturing companies address long-term skill needs. These partnerships may involve:

- Co-developing curricula that align with industry needs

- Offering internships and co-op programs to students

- Providing guest lectures and workshops by industry experts

- Sponsoring research projects in relevant fields

By fostering these relationships, companies can help shape the future workforce and gain early access to emerging talent.

Leveraging Online Learning Platforms

Online learning platforms offer flexible, scalable solutions for continuous skill development. Companies can leverage these platforms to:

- Provide on-demand access to training materials and courses

- Facilitate self-paced learning for employees with varying schedules

- Offer micro-learning modules for just-in-time training on specific topics

- Track employee progress and identify areas for additional support

Integrating online learning with traditional training methods creates a comprehensive approach to skill development.

Emphasis on Soft Skills Development

While technical skills are crucial in computer manufacturing, soft skills are equally important for career advancement and effective teamwork. Training programs should include modules on:

- Communication and presentation skills

- Project management and leadership

- Problem-solving and critical thinking

- Adaptability and resilience

- Cultural awareness for global operations

Developing these soft skills alongside technical expertise creates well-rounded professionals capable of driving innovation and leading teams.

Challenges in Implementing Tech Skills Training

Keeping Pace with Technological Advancements

The rapid evolution of technology in computer manufacturing presents a significant challenge for training programs. Companies must continuously update their curricula and training materials to reflect the latest advancements, which can be resource-intensive.

Balancing Production Demands with Training Time

In a fast-paced manufacturing environment, finding time for training without disrupting production schedules can be challenging. Companies need to develop strategies for integrating learning into the workflow without compromising productivity.

Measuring ROI and Effectiveness

Quantifying the return on investment for training programs can be difficult, particularly for soft skills development. Developing robust metrics and assessment methods is crucial for demonstrating the value of training initiatives to stakeholders.

Addressing Diverse Learning Needs

With a workforce spanning multiple generations and educational backgrounds, creating training programs that cater to diverse learning styles and preferences can be challenging. Personalization and adaptability in training delivery are key to addressing this issue.

Retention of Skilled Workers

As employees develop valuable skills through training programs, there’s a risk of losing them to competitors offering better opportunities. Companies must develop strategies for retention, including clear career progression paths and competitive compensation packages.

Best Practices for Implementing Tech Skills Training

Align Training with Business Objectives

Ensure that training initiatives are closely tied to the company’s strategic goals and market demands. This alignment helps justify investments in training and demonstrates its value to all stakeholders.

Foster a Culture of Continuous Learning

Promote a workplace culture that values and rewards continuous learning and skill development. This can be achieved through:

- Recognition programs for skill acquisition and application

- Incorporating learning goals into performance evaluations

- Providing time and resources for self-directed learning

Utilize a Mix of Training Methods

Combine various training methods to cater to different learning styles and maximize engagement. This may include:

- Instructor-led classroom sessions

- E-learning modules

- Virtual and augmented reality simulations

- On-the-job training and mentoring

- Peer-to-peer learning initiatives

Implement Regular Skills Assessments

Conduct regular skills assessments to identify gaps and track progress. Use these insights to refine training programs and provide targeted support to employees.

Encourage Knowledge Sharing

Create platforms and opportunities for employees to share their expertise and experiences. This can include:

- Internal tech talks and workshops

- Mentoring programs

- Collaborative problem-solving sessions

- Documentation of best practices and lessons learned

Stay Informed About Industry Trends

Maintain close connections with industry associations, attend conferences, and engage with research institutions to stay informed about emerging trends and technologies. Use this knowledge to proactively update training programs.

Seek Employee Feedback

Regularly solicit feedback from employees on the relevance and effectiveness of training programs. Use this input to make continuous improvements and ensure that training meets the workforce’s needs.

Training Programs by Industry Leaders

Intel’s AI for Workforce Program

Intel’s AI for Workforce Program is a comprehensive initiative designed to bridge the AI skills gap in the United States. The program collaborates with community colleges to develop and implement AI curricula, focusing on both theoretical knowledge and practical applications.

Key aspects of the program include:

- Courses covering machine learning, deep learning, computer vision, and natural language processing

- Hands-on labs using Intel’s AI development tools like OpenVINO toolkit and Intel DevCloud

- Training in AI ethics and responsible AI development

- Industry-relevant projects using real-world datasets

- Access to Intel’s AI experts for mentorship and guidance

The program benefits Intel by creating a pipeline of AI-skilled talent, potentially leading to future recruitment. For participants, it offers a pathway into the rapidly growing field of AI, enhancing their employability in the tech sector.

TSMC’s Training and Development System

Taiwan Semiconductor Manufacturing Company (TSMC) has implemented a multi-faceted training system that covers the entire employee lifecycle. This system is crucial for maintaining TSMC’s technological edge in semiconductor manufacturing.

The training system includes:

- Orientation training: Covering company culture, basic semiconductor physics, and clean room protocols

- On-the-job training: Hands-on experience with cutting-edge semiconductor fabrication equipment

- Advanced process technology training: Focusing on nanometer-scale manufacturing techniques

- Continuous learning programs: Regular updates on emerging technologies like extreme ultraviolet (EUV) lithography and 3D chip stacking

- Leadership development: Grooming future leaders with both technical and managerial skills

- Virtual reality (VR) simulations: For safe practice of complex manufacturing processes

This comprehensive approach ensures that TSMC’s workforce remains at the forefront of semiconductor technology, contributing to the company’s continued leadership in the industry.

Foxconn’s Robotics Training Program

Foxconn’s Robotics Training Program is a response to the increasing automation in electronics manufacturing. The program aims to upskill workers, transforming them from manual laborers to skilled robotics technicians and operators.

The program covers:

- Fundamentals of robotics and automation

- Programming industrial robots using languages like KUKA Robot Language (KRL) and ABB’s RAPID

- Maintenance and troubleshooting of robotic systems

- Integration of robots with other manufacturing systems (e.g., conveyor belts, vision systems)

- Collaborative robot (cobot) operation and safety

- Data analysis for optimizing robotic processes

This initiative helps Foxconn maintain efficiency in its highly automated factories while providing employees with valuable skills for the future of manufacturing.

Dell Technologies’ Tech Skills Initiative

Dell Technologies’ Tech Skills Initiative is a broad-ranging program aimed at equipping its workforce with skills in emerging technologies. The initiative covers several key areas:

- Cloud Computing: Training on major cloud platforms (AWS, Azure, Google Cloud), cloud architecture, and DevOps practices

- Cybersecurity: Courses on network security, ethical hacking, and security information and event management (SIEM) tools

- Artificial Intelligence and Machine Learning: Programs covering data science, predictive analytics, and AI model development

- Internet of Things (IoT): Training on IoT protocols, edge computing, and IoT security

- Blockchain: Introduction to distributed ledger technologies and their applications in supply chain and data management

The initiative includes both online learning platforms and in-person workshops, often partnering with technology vendors for specialized training. This comprehensive approach ensures that Dell’s workforce remains adaptable and innovative, capable of developing cutting-edge solutions for customers across various industries.

HP’s Digital Manufacturing Academy

HP’s Digital Manufacturing Academy is a pioneering program focused on advanced manufacturing technologies. The academy’s curriculum is designed to transform HP’s manufacturing capabilities and accelerate its digital transformation.

Key components of the academy include:

- 3D Printing Technologies: Comprehensive training on various 3D printing methods, materials science, and post-processing techniques

- Additive Manufacturing Design: Courses on design for additive manufacturing (DfAM) principles and topology optimization

- Industrial IoT and Smart Factory Concepts: Training on implementing sensors, data analytics, and predictive maintenance in manufacturing

- Robotics and Automation: Programs covering collaborative robots, automated guided vehicles (AGVs), and robotic process automation (RPA)

- Digital Twin Technology: Training on creating and utilizing digital twins for product development and manufacturing optimization

- Augmented Reality in Manufacturing: Courses on using AR for assembly guidance and quality control

The Digital Manufacturing Academy not only enhances HP’s manufacturing capabilities but also positions the company as a leader in the Industry 4.0 revolution. Employees gain cutting-edge skills that are increasingly valuable across the manufacturing sector, improving both their career prospects and HP’s competitive advantage.

These expanded training programs demonstrate how leading companies in computer manufacturing are investing in their workforce to stay ahead in a rapidly evolving technological landscape. By providing comprehensive, forward-looking training, these companies are not only improving their own capabilities but also contributing to the overall advancement of the tech industry workforce.

Embracing the Human Element in Computer Manufacturing

The world of computer manufacturing isn’t just about circuits and silicon – it’s about people. Behind every sleek laptop, powerful server, or cutting-edge smartphone, there’s a team of skilled individuals bringing these marvels to life. As we’ve explored throughout this article, empowering these people with the right tech skills isn’t just a nice-to-have; it’s absolutely crucial for staying ahead in this fast-paced industry.

The devices we rely on daily are becoming more complex, more powerful, and more integrated into every aspect of our lives. The people creating these devices need to be just as adaptable, just as innovative, and just as forward-thinking as the technology they’re building.

That’s where robust training and development programs come in. They’re not just about ticking boxes or fulfilling corporate requirements. They’re about nurturing talent, sparking curiosity, and building a workforce that’s ready to tackle whatever challenges tomorrow might bring. It’s about creating an environment where learning isn’t a chore, but an exciting journey of discovery.

The most successful enterprises in computer manufacturing will be those that fundamentally understand this principle. These organizations will recognize their employees not as mere components in a production system, but as the core drivers of innovation. They will allocate resources to personnel development with the same strategic priority as they do to research and development initiatives. Such companies will foster an organizational culture that promotes intellectual curiosity, rewards innovative thinking, and facilitates continuous learning across all levels of the organization, from production personnel to executive leadership.

As we look to the future, it’s clear that the real game-changers in computer manufacturing won’t just be the ones with the most advanced technology. They’ll be the ones with the most empowered, skilled, and passionate people. Because at the end of the day, it’s not just about building better computers – it’s about building a better, more capable workforce that can dream up and create the technologies of tomorrow.

So, let’s embrace this challenge with open arms. Let’s commit to nurturing the talents and skills of the people who make our digital world possible. Because when we invest in people, we’re not just shaping the future of computer manufacturing – we’re shaping the future of technology itself. And that’s an adventure worth embarking on.

Recent Blogs

Unleashing the i7 Processor Power with Holoware

Choosing the Perfect IPS Screen Laptop by Holoware

Holoware - Choosing a Laptop with Dedicated Graphics Card

Holoware's Best Budget Laptop for Programming

i9 Processor Laptops: Power & Performance at Holoware

The Rise of Thin and Light Laptops at Holoware

Holoware: Why a 4GB Graphics Card for PC Is Essential

8GB DDR4 RAM for Laptop: Boost Performance with Holoware

Holoware's Latest Generation of Laptop

AI Indian Laptop: Holoware Sets a New Standard for Indian AI PCs

About Holoware

Products & Services

Useful Links

©2024 Holoware® Computers Pvt. Ltd. | Site Map | Privacy Policy | Terms & Condition

Location: Porur,Chennai

No of Openings: 1

Join our team as a Senior Accounts Executive, where you’ll manage client relationships and implement innovative financial strategies. Your expertise in analyzing account performance will drive growth and foster lasting partnerships. If you’re ready to make an impact, we want to hear from you.

Roles and Responsibilities:

- Daily Accounts Receivable Management: Execute daily credit accounting in Tally Prime to ensure accurate financial records.

- Accounts Receivable and Credit Control Management: Administer the accounts receivable process and implement credit control measures to optimize cash flow.

- Invoice Processing and Material Transfers: Handle invoice cancellations and efficiently oversee the transfer of materials to the warehouse.

- Sales Returns and Order Cancellations Management: Process sales returns, record entries, create Post Goods Issues (PGI), and reverse canceled orders for precise sales tracking.

- Dealer Loan Recovery Supervision: Manage the recovery of dealer loans, accurately reflecting these amounts as recoverable income.

- Dealer Debit Data Reporting: Upload monthly dealer debit information to Power BI through Microsoft Azure for accurate financial analysis.

- Bank Reconciliation Tasks: Conduct detailed bank reconciliations to ensure transaction accuracy and resolve any discrepancies.

- Customer Account Reconciliation: Reconcile customer accounts with the General Ledger (GL) to ensure data consistency and accuracy.

- General Ledger Review: Perform monthly reviews of GL accounts to ensure compliance and accuracy in financial reporting.

- Monthly Sales Report Preparation: Compile and present monthly sales flash reports, offering insights into sales performance and trends.

- Monthly Financial Closing Procedures: Manage the monthly closing process, finalizing financial statements and recording all transactions.

- Tax Compliance Management: Prepare and submit Tax Deducted at Source (TDS) returns and issue Form 16 and Form 16A for compliance purposes.

- Employee Payroll Administration: Oversee the timely and accurate processing of employee salaries in line with payroll policies.

- Project Bills and Payment Oversight: Oversee the management of project bills payable, ensuring timely processing of payments to vendors and contractors.

- Project Budget Allocation Management: Allocate project budgets according to expense categories, ensuring effective financial resource utilization.

- GST Compliance Oversight: Manage Goods and Services Tax (GST) returns and TDS calculations to ensure accurate reporting and compliance.

- Audit Coordination: Collaborate with internal and external auditors, providing all necessary documentation for smooth audit processes.

- Audit Process Coordination: Facilitate internal and Auditor General (AG) audits by preparing all necessary documentation for review.

- Government Fund Allocation Liaison: Work with government agencies to coordinate fund allocations, ensuring compliance with regulations.

- Monthly Management Information Reporting: Prepare and present detailed Monthly Management Information System (MIS) reports to senior management.

Key Skills:

- Accounting

- Financial Reporting

- Tally Prime

- Data Analysis

- Reconciliation

- Tax Compliance

- Negotiation

- Problem-Solving

- Time Management

- Team Collaboration

- Vendor Management

Location: Porur,Chennai

No of Openings: 4

Join our team as a Senior Hardware Engineer to design and optimize state-of-the-art computing systems. You’ll leverage your expertise to innovate hardware solutions, ensuring peak performance and reliability in our products. Collaborate with a talented team to tackle complex challenges and help shape the future of technology.

Roles & Responsibilities:

- Lead the assembly process of desktops, laptops, and servers ensuring adherence to technical specifications and quality standards.

- Supervise and train a team of assembly technicians and junior engineers, providing guidance and feedback.

- Collaborate with the R&D and design teams to implement manufacturing processes for new products.

- Develop and optimize workflow to increase efficiency and reduce assembly times and costs.

- Maintain detailed documentation of assembly procedures and product modifications.

- Conduct quality control checks and troubleshoot hardware issues before final product release.

- Ensure compliance with safety standards and regulations in the assembly line.

- Manage inventory of parts and tools required for assembly processes.

- Stay updated with industry trends, new technology, and best practices in hardware assembly.

Preferred candidate profile:

- Bachelor’s degree in Electrical Engineering, Mechanical Engineering, or a related field.

- Minimum of 5 years of experience in hardware assembly, preferably focusing on PCs, laptops, and servers.

- The maximum age limit is 42 years

- Proven track record of leading a team in a manufacturing or assembly environment.

- Strong technical skills with a deep understanding of computer hardware components and assembly techniques.

- Excellent problem-solving skills and attention to detail.

- Proficient in using assembly tools and equipment.

- Certifications related to hardware assembly or project management.

- Experience in an ISO-certified or other regulated environment.

Key Skills:

- Service Engineering

- Hardware Networking

- Computer Hardware

- Team Leading

- Chip Level Repairing

- After Sales – Service and Support

- Computer Assembling

Location: Porur,Chennai

No of Openings: 2

Seeking a Senior Executive – International Purchase to spearhead global procurement strategies and secure top-tier suppliers. Harness your expertise to drive cost efficiencies, negotiate high-impact deals, and ensure seamless cross-border operations. Ideal candidates excel in strategic sourcing and thrive in a dynamic, fast-paced environment. Elevate our international purchasing with your strategic vision and industry insight.

Roles and Responsibilities:

- Develop and implement procurement strategies that are cost-effective and aligned with the company’s production needs and budget constraints.

- Identify, evaluate, and select reliable vendors and suppliers. Negotiate contracts and terms of agreements to achieve favourable pricing and delivery terms.

- Maintain optimal levels of inventory to ensure uninterrupted production schedules while minimizing carrying costs and obsolescence.

- Ensure that all purchased items meet quality standards and specifications required by the production process.

- Monitor and control procurement budgets and expenditures. Implement cost-saving initiatives without compromising on quality or reliability.

- Coordinate with production planning and logistics teams to ensure timely availability of materials and components.

- Stay updated with regulatory requirements and ensure procurement activities comply with legal standards and company policies.

- Identify potential risks in the supply chain and develop mitigation strategies to avoid disruptions in production.

- Analyse procurement data and market trends to make informed decisions and optimize purchasing strategies.

- Build and maintain strong relationships with vendors, suppliers, and internal stakeholders to foster collaboration and achieve mutual goals.

Preferred Candidate Profile:

- Proven experience as a Purchase or in a similar role.

- Should have a strong International Procurement experience.

- Strong negotiation skills and the ability to build long-term relationships with suppliers.

- Excellent communication and interpersonal skills.

- Familiarity with supply chain processes and inventory management.

- Bachelors degree in Business Administration, Supply Chain Management, or relevant field.

Location: Porur,Chennai

No of Openings: 2

Dynamic Logistics Executive sought to streamline supply chain operations and optimize distribution networks. Leverage your expertise to drive efficiency, enhance customer satisfaction, and lead innovative solutions. Ideal candidates are proactive problem-solvers with a knack for strategic planning and team leadership. Join us to make a tangible impact in a fast-paced environment!

Roles and Responsibilities:

Imports:

- Receiving the documents from overseas Agents.

- Documents are forwarded to various Liner for IGM filing purposes.

- Follow up on the vessel status for all import shipments through online.

- Providing the vessel details and the IGM number to the consignee once their shipment arrives.

- Issuing the Delivery order to a variety of consignees.

- Regular communication with All Liners/Consignee & Overseas Agent for all Import Shipments.

- As per the Shipper Invoice & Packing List, have prepared the shipment checklist.

- Preparing the necessary documents for clearance purposes

- Regular interaction with Liner for all the shipments.

- BE filing follow-up with CHA and transport movement

- Follow up on the status of all the shipments and inform the same to the respective shipper

- Preparing the Invoices of Various parties.

- Planning for day-to-day clearance on a priority basis.

Exports:

- Booking the cargo for all export shipments to Liner / Consolidator.

- Arranging the Container Release order from the liner and forwarding to the Shipper or CHA

- Informing liner to post the form-13 to CHA ID

- Follow up the container to load on the booking vessel.

- Preparing the Bill of Lading through on-line to various sector

- Based on the Liner invoice, have generated our Invoice for Customers.

- Issuing the Bill of Lading/COO/SCOMET

- Co-ordinating with all Overseas agents/Liner / Shipper/CHA for all export shipments.

- Scrutiny the Freight rates from the Liner / Consolidator and provide the best rate to the shipper).

- SB filing follow-up with CHA and transport movement

Preferred Candidates Profile:

- Tally /SAP/ERP knowledge required.

- Should be strong in Shipping INCOTERMS

- Preparing the Profit & Loss for all shipments (Import & Export)

Location: Bangalore, Hyderabad & Mumbai

No of Openings: 5

We are seeking a Key Account Manager for Corporate Sales who plays a crucial role in driving revenue growth, maintaining strong client relationships, and ensuring customer satisfaction within key accounts. Their responsibilities require a blend of strategic thinking, interpersonal skills, and a deep understanding of both the client’s business and their own company’s offerings.

Preferred Candidate profile:

- Excellent communication, interpersonal and relationship-building skills

- Should have a strong experience in B2B sales.

- Ability to work both independently and collaboratively in a team setting.

- Keen analytical skills and a strategic mindset.

- Willingness to travel for business purposes.

- Proven track record in lead generation and communication

- Ability to work independently and collaboratively

- Experience in the IT hardware/ Technology industry is a plus

- Experience in handling the IT/ITES, Manufacturing, Engineering, Media, BFSI Enterprise accounts is a plus

- Knowledge of IT hardware products is a plus

- Languages: Local Regional language and English are a must; Tamil & Hindi will be an added advantage.

- Preferred experience is 5 to 12 years in the relevant field.

Roles & Responsibilities:

- Establishing and maintaining a strong rapport with the enterprise accounts and the Channel partners in the assigned territories.

- Develop and execute strategic plans to achieve sales targets and expand the company’s customer base within key accounts

- Responsible for selling Artificial Intelligence (AI) Laptops, PCs and other Business Laptop, Executive Laptop, Desktops & Workstations.

- Coordinate with internal teams to ensure contract specifications are met on schedule.

- Analyse market trends and competitor activities to adjust strategies accordingly.

- Create and present detailed reports and presentations for various stakeholders.

- Business Development, Meeting the customers F2F Daily.

- Getting new Logos, generating leads, and providing excellent customer service.

- Drive existing accounts and get new business through SI’s and Large partners.

Location: Porur,Chennai

Languages: Hindi, Kannada, Telugu, Malayalam

No of Openings: 5

We are seeking a motivated and detail-oriented Business Analyst to join our dynamic sales team. The Business Analyst will play a key role in supporting our sales representatives and ensuring smooth operations within the sales department. This position offers an exciting opportunity to contribute to the success of our sales initiatives and provide excellent customer service to our clients.

Roles and Responsibilities:

- Identify potential customers interested in laptops, desktops, and tablets.

- Reach out to these prospects via phone or email to introduce the products.

- Discuss with customers to determine their specific requirements and preferences.

- Recommend and demonstrate the laptops, desktops, and tablets that best fit their needs.

- Track and manage leads through the sales cycle using CRM tools.

- Negotiate terms and close sales for the desired devices.

- Maintain communication with clients to ensure their satisfaction and encourage repeat business.

- Provide updates on sales performance and progress towards targets.

- Coordinate with technical support and product teams to address any issues or questions.

- Prepare and manage quotes, orders, and other sales-related documentation.

Preferred Candidates Profile:

- A bachelor’s degree in business administration, marketing, or a related field is preferred.

- Hindi or other regional languages are preferred.

- Proven experience in a sales support or coordination role, preferably in the technology industry.

- Strong organizational skills with the ability to manage multiple tasks simultaneously and prioritize effectively.

- Excellent communication and interpersonal skills, with a customer-focused approach.

- Proficiency in Microsoft Office suite (Word, Excel, PowerPoint) and CRM software.

- Attention to detail and high accuracy in data entry and record-keeping.

- Ability to work independently and as part of a team in a fast-paced environment.

- Positive attitude, willingness to learn, and adaptability to changing priorities.

Perks and Benefits:

- Opportunity to work with cutting-edge technology and innovative products.

- Collaborative and supportive work environment.

- Career growth and development opportunities within a growing company.

- Make a meaningful impact by contributing to the success of our sales team and driving business growth.

Location: Bangalore & Kochi

No of Openings: 2

We are seeking a Government Sales Specialist with exceptional communication skills and a deep understanding of government operations and procurement processes. This role is ideal for individuals with a strong background in public administration or related fields, who are adept at strategic engagement and building a long-term governmental relationship.

Preferred Candidate profile:

- Proven track record in sales with a focus on government sector engagements.

- Able to manage the GeM (Govt e-Marketplace) portal and Govt tenders.

- Exceptional verbal and written communication skills.

- Strong experience working with CXOs & Procurement Managers.

- Should have a strong experience in stock & sell.

- Ability to work both independently and collaboratively in a team setting.

- Keen analytical skills and a strategic mindset.

- Willingness to travel for business purposes.

- Preferred experience is 5 to 12 years in the relevant field.

- Strong knowledge in handling the state & central government departments within the whole Kerala/Karnataka/Mumbai state.

Roles & Responsibilities:

- Develop and implement effective sales strategies tailored to government sectors.

- Navigate and comply with government procurement policies and regulations.

- Build and maintain robust relationships with key stakeholders within government entities.

- Responsible for selling Artificial Intelligence (AI) Laptops, PCs and other Business Laptop, Executive Laptop, Desktops & Workstations.

- Coordinate with internal teams to ensure contract specifications are met on schedule.

- Analyze market trends and competitor activities to adjust strategies accordingly.

- Create and present detailed reports and presentations for various stakeholders.

Location: Porur,Chennai

No of Openings: 5

As a Level 2 Customer Support Specialist, you will serve as the primary point of contact for customers requiring advanced technical support for desktop/laptop-related issues. You will troubleshoot, resolve, and escalate complex problems, providing exceptional customer service and ensuring customer satisfaction.

Roles and Responsibilities:

- Respond to customer inquiries via phone, email, or chat, resolving Level 2 technical issues related to desktop/laptop hardware, software, and peripherals.

- Troubleshoot and diagnose complex problems using advanced technical knowledge and tools.

- Provide timely and effective solutions, escalating issues to senior technicians or management when necessary.

- Document customer interactions, issues, and resolutions in our CRM system.

- Collaborate with internal teams (e.g., sales, technical) to resolve customer concerns and improve processes.

- Stay up-to-date with industry developments, new technologies, and company products/services.

- Meet or exceed customer satisfaction, first-call resolution, and other performance metrics.

Preferred Candidates Profile:

- 2+ years of experience in technical support, preferably in a desktop/laptop service company.

- Advanced knowledge of desktop/laptop hardware, software, and peripherals.

- Excellent problem-solving, analytical, and communication skills.

- Ability to work in a fast-paced environment, prioritizing tasks and managing time effectively.

- Strong customer service skills, with a focus on empathy and professionalism.

Sample Form

Rugged Laptop

Rugged Tablet

Tablets

Demo Available*

Inquire About Rental Options

Warranty Offers

- Extended Protection: Warranty offers cover repairs and replacements for hardware failures or defects, saving significant costs on expensive components.

- Professional Support: They provide access to authorized service centers and professional support, ensuring quality repairs with genuine parts.

Services with those steps are available

- Accidental Damage Coverage: Some warranties include coverage for accidental damage, such as drops or spills, providing extra protection beyond standard defects.

- Technical Support: Many warranties offer round-the-clock technical support to help with troubleshooting and resolving software or hardware issues.

- Data Recovery Services: In case of hardware failure, some warranty plans include data recovery services to help retrieve important files and documents.

Solution With 24/7 Support

- 24/7 Technical Support: Many warranty plans provide round-the-clock technical support to assist with troubleshooting and resolving software or hardware issues at any time.

- On-Site Repairs: Certain warranty plans offer on-site repair services, where technicians come to your location to fix issues, minimizing downtime.

- Loaner Devices: Some warranties provide loaner devices while your laptop is being repaired, ensuring you stay productive without interruption.

- Global Coverage: For frequent travelers, some warranty plans offer global coverage, ensuring you can get support and repairs no matter where you are

Get Started

Please enable JavaScript in your browser to complete this form. |

In 1994, Mr.Thangavel started Origin Information Technology (in partnership with Mr. Loganathan) to provide quality computer hardware sales and service. In the year 2022, the company name was changed to “Tinkas Industries Private Limited” to encompass its diversified activities. Mr. Thangavel feels that he can give back to his nation the growth it needs in many ways like providing employment opportunities to many, and doing CSR activities, etc. His goal is to make Tinkas a leader at the National and Internaltional levels.

Holoware CEO abut Tinkas CEO

“The CEO of Tinkas (Mr.Thangavel) is undeniably one of the most practical and resourceful individuals I’ve encountered in Tamil Nadu. His profound understanding of the industry coupled with his diverse business ventures truly exemplifies his wealth of knowledge. Partnering with Tinkas has been a delight, and we eagerly anticipate further growth and collaboration.”

Mr. Ketan Patel is an indomitable entrepreneur revolutionizing the landscape of electronic consumer products worldwide through an unparalleled ‘experiential journey.’ Leading Creative Newtech since 1992, he steered its growth from a Mumbai market trader to a distributor and Brand Licensee. As an alumnus of IIM-Bangalore, Mr Patel leads Creative Newtech with a focus on innovation and strategic leadership. Under his three-decade leadership, Creative Newtech has become India’s market leader, expanding globally across Hong Kong, the Middle East, and the SAARC region.”

Holoware CEO abut Creative Newtech CEO

“The CEO of Creative (Mr.Ketan Patel) is a highly knowledgeable leader, renowned for his expertise in distributorship. His intuitive knack for product selection and sales strategies, both in India and abroad, is impressive. Creative thrives as a powerhouse, fueled by its diverse team and collective expertise. We eagerly look forward to a promising future and further success in our collaboration with Creative.”

Inmac Computers Private Limited is a trailblazing name in the realm of IT services and solutions. With a remarkable inception in 1992 by visionary entrepreneurs Girish Babu and Asha Girish Babu, our company has consistently remained at the forefront of technological innovation, setting new standards for excellence in the industry.

Holoware CEO abut Inmac CEO

“Inmac’s CEO (Mr.Girish Babu) is one of the most humble and generous individuals I’ve ever had the pleasure of meeting. His leadership has been instrumental in steering his team to success, not just in Maharashtra but across various regions in India. Their financial stability over the years speaks volumes about his capabilities. It’s truly a delight to collaborate with someone of his caliber. I look forward to continued partnership with Inmac.”